WHERE’D IT COME FROM? A BRIEF HISTORY OF CASHMERETTE, AUTO UPHOLSTERY, TOOTHPICKS, AND HEART PINE TIMBERS.

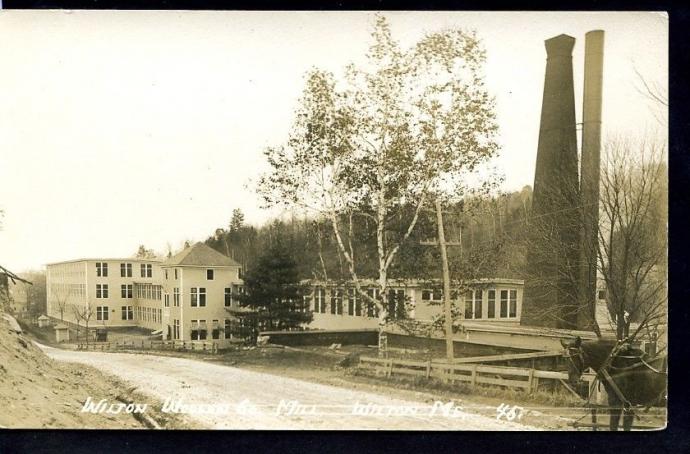

Long Leaf Southern Yellow Pine, aka Heart Pine, is called “the wood America was built with” due to its prevalence in construction during the Industrial Revolution. The Wilton Woolen Mill was no exception, though it was built towards the tail end of this revolution (1840) in Wilton, Maine. We’re excited to usher over 750 Heart Pine post and beam timbers salvaged during the deconstruction to new uses.

While the mill has a colorful history (see below), its timber bones are where our obsession lies. Antique Heart Pine is no longer available through fresh-sawn means and has unmatched characteristics. Containing a high amount of resin, Heart Pine is desirable for its clean grain, durability, and thanks to that resin, when re-sawn has a distinct “glow” of warmth. Golds, oranges, and a variety of deeper patina define the species which is nearly as hard as Oak.

The Wilton Woolen Mill:

Completed in 1901 over 232,000 square feet of interconnected wood buildings were owned by Frank and George Goodspeed who set the factory up to produce cashmerette, a cotton wrap fabric used in overshoes prior to the development of rubber shoes. The Wilton Woolen Mill was the sole manufacturer of cashmerette until demand dwindled in 1924. Upon the death of the Goodspeeds, a group of local Wilton men interested in preserving the welfare of the community purchased the mill from the estate. They maintained operations of the mill with a focus on community—donating over $100,000 to the Wilton Academy Gym and Community Center.

With cashmerette out of demand, the mill turned to producing auto upholstery and women’s wear fabrics. The auto fabric included headliners, seat backs, and side walls used by General Motors, Chrysler, and Ford. For a number of years, nearly 50% of the auto industry upholstery was made in the Wilton Mill. In 1950 the mill manufactured approximately 10 million yards of various textiles for the armed services, receiving the Army-Navy “E” Flag award for their efforts.

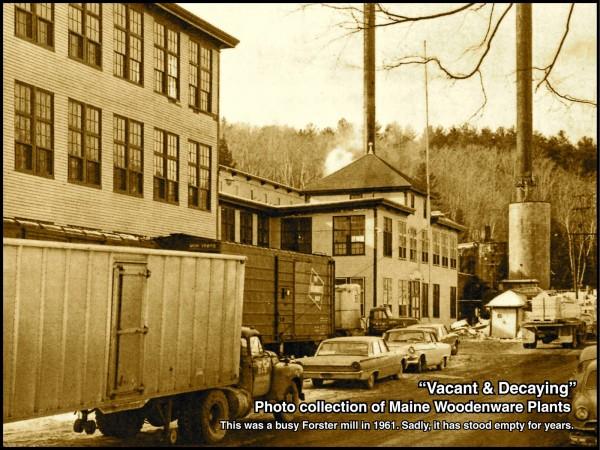

The mill closed in 1955 as wool prices continued to climb. It sat empty until purchased by the Forster Manufacturing Company in 1960. With five plants, over 330-line workers, and 100 office employees—Forster designed the Wilton Mill as their headquarters, housing the general offices and central warehouse for the company. The plant began manufacturing croquet sets, toothpicks, custom turnings, and assembled snap clothespins. In 1985 Forster closed all services, citing severe foreign competition.

The Jarden Corp. stepped into the space and made plastic cutlery for a brief time before closing in 2003. Ownership transferred again, and the mill sat empty and deteriorating from 2004–2012 when arrangements were made for deconstruction. The hybrid deconstruction required the world’s largest excavators to gently take down the four-story structure and salvage various materials. A slow and careful process, the timbers that were piled on the deconstruction site are now neatly stacked in our yard under the careful watch of our yard team.